ABOUT

Smart Manufacturing & Simplified

The DQ Manufacturing Execution System (MES) is a cloud-based solution designed to streamline and optimize your production process. Acting as the central hub, it connects people, machines, and data, providing real-time insights that enable better control, faster decisions, and more efficient operations.

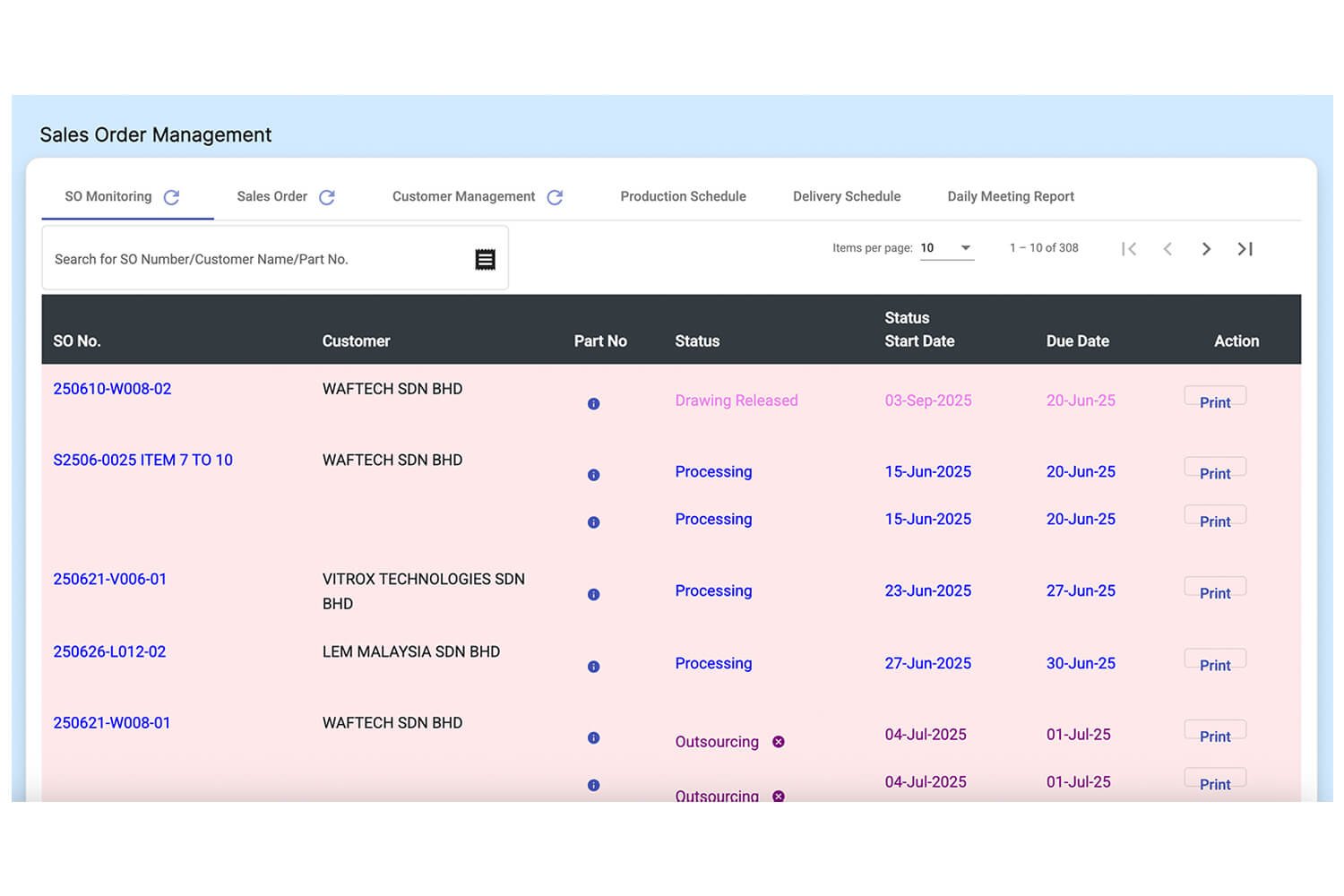

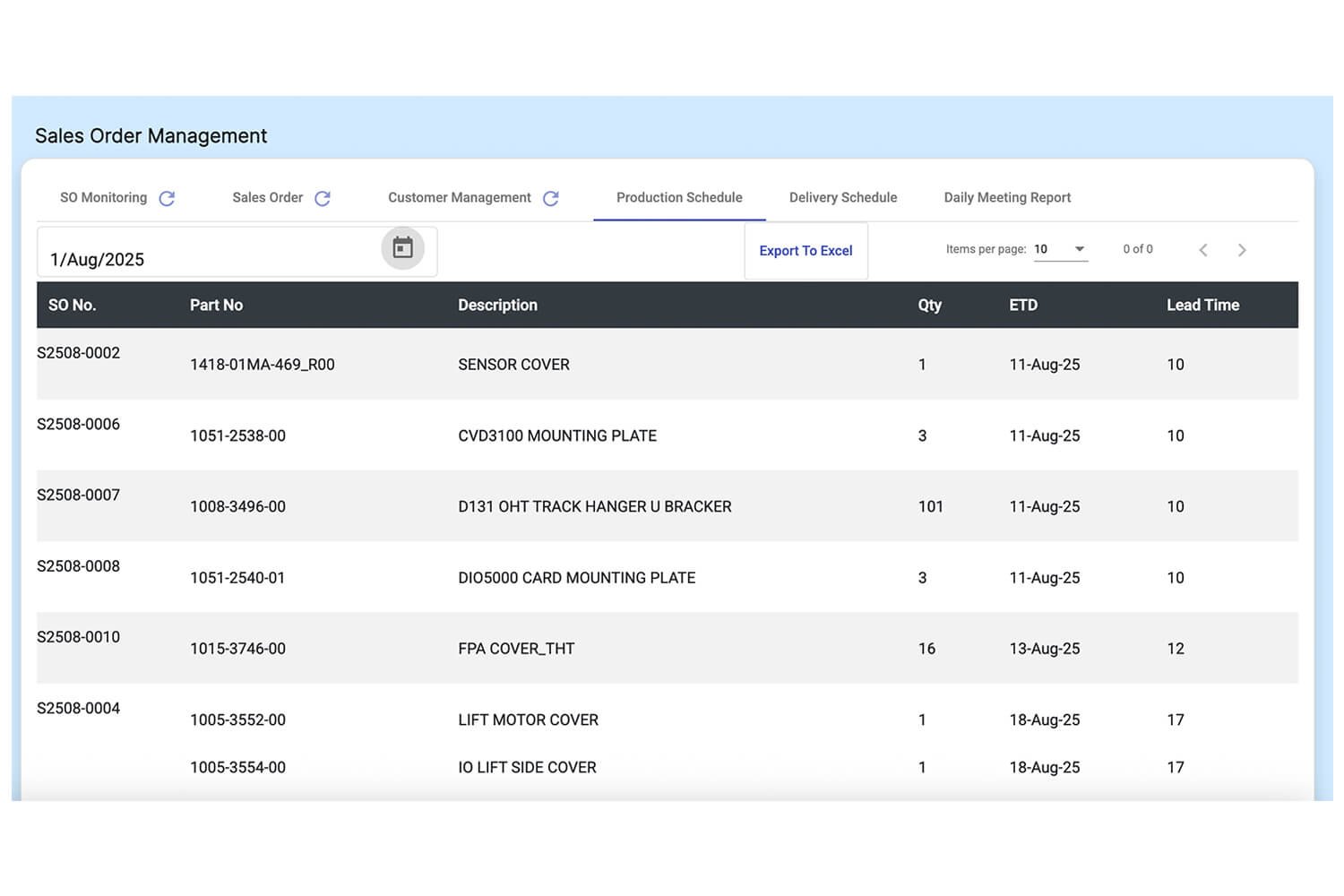

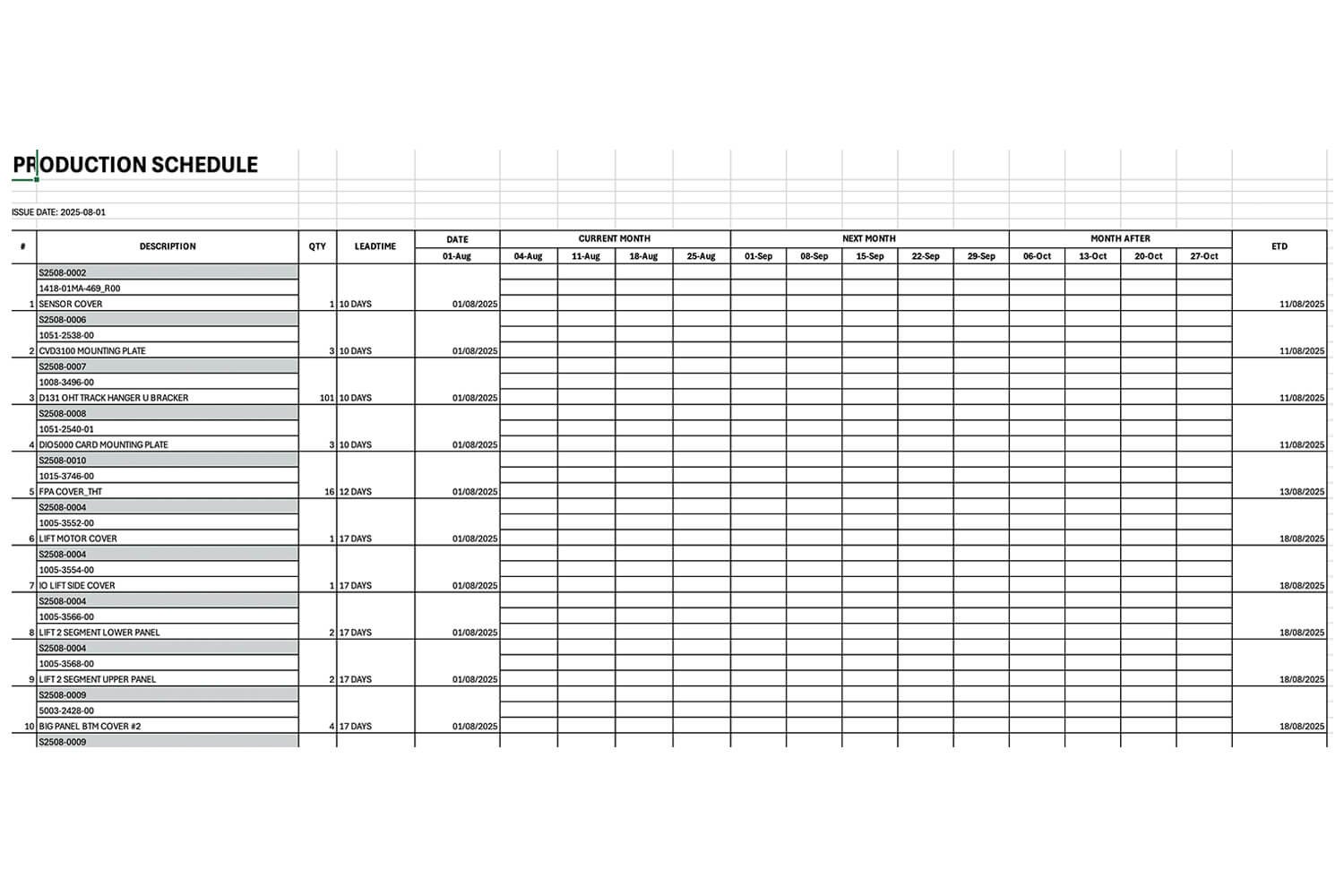

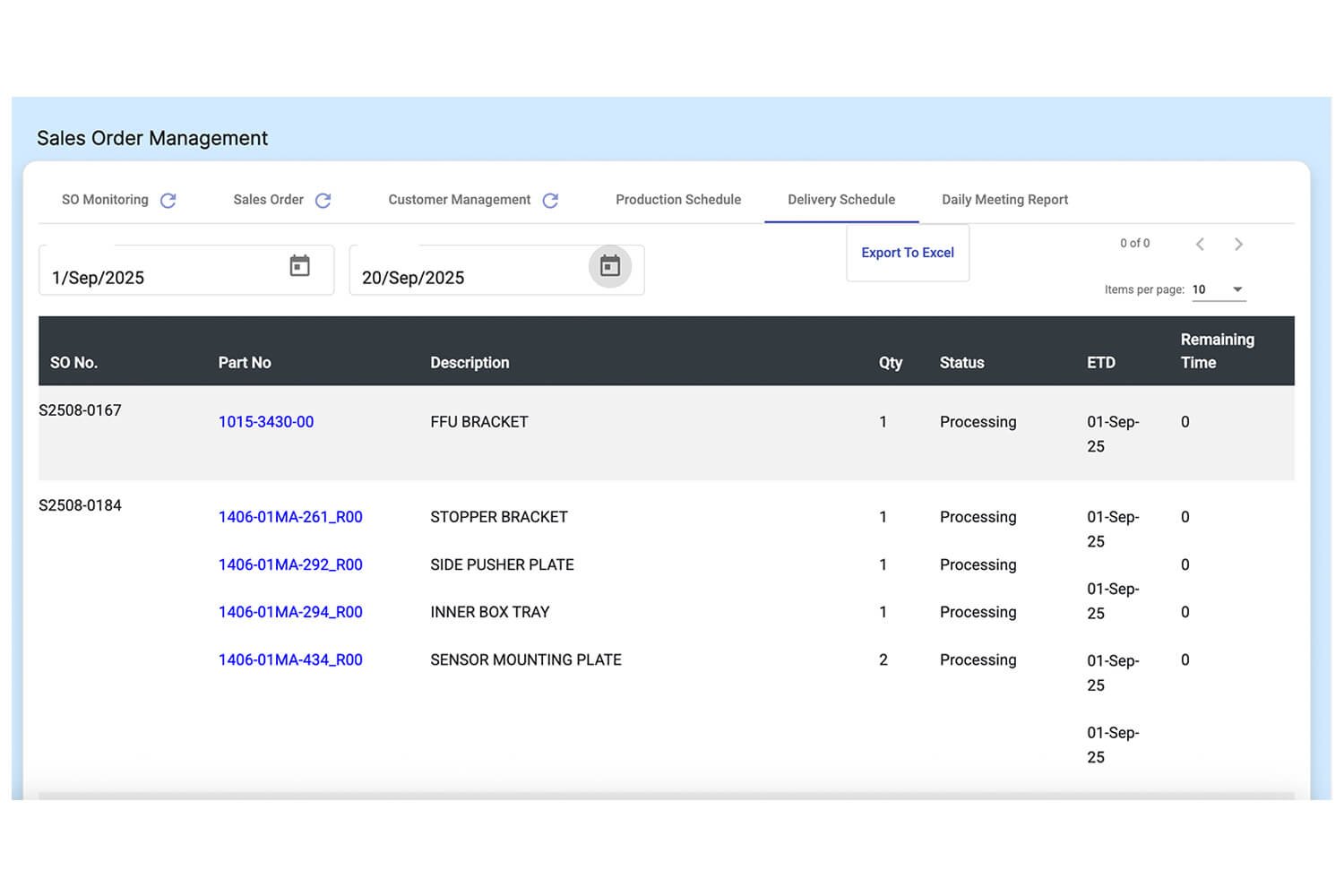

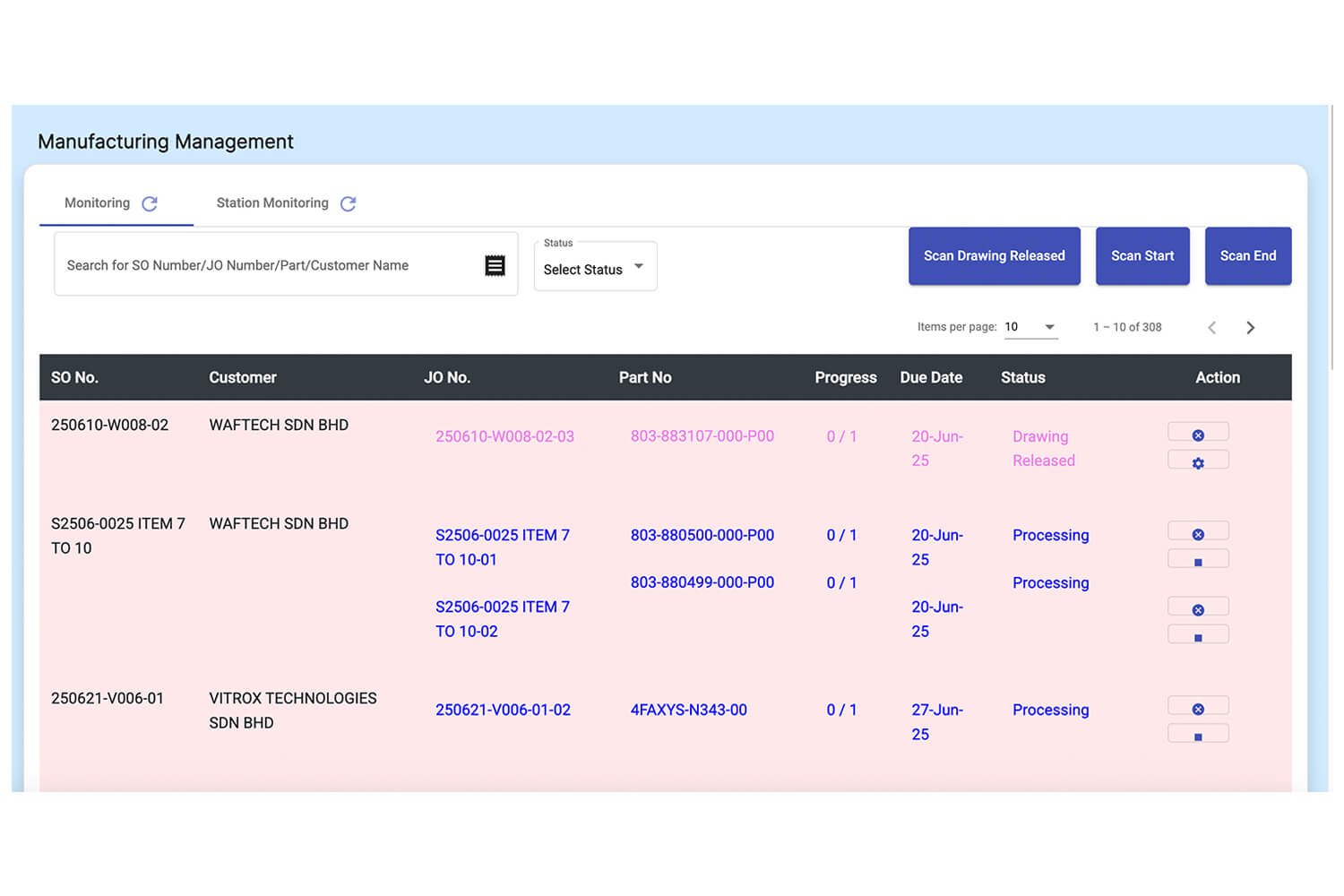

FUNCTIONS

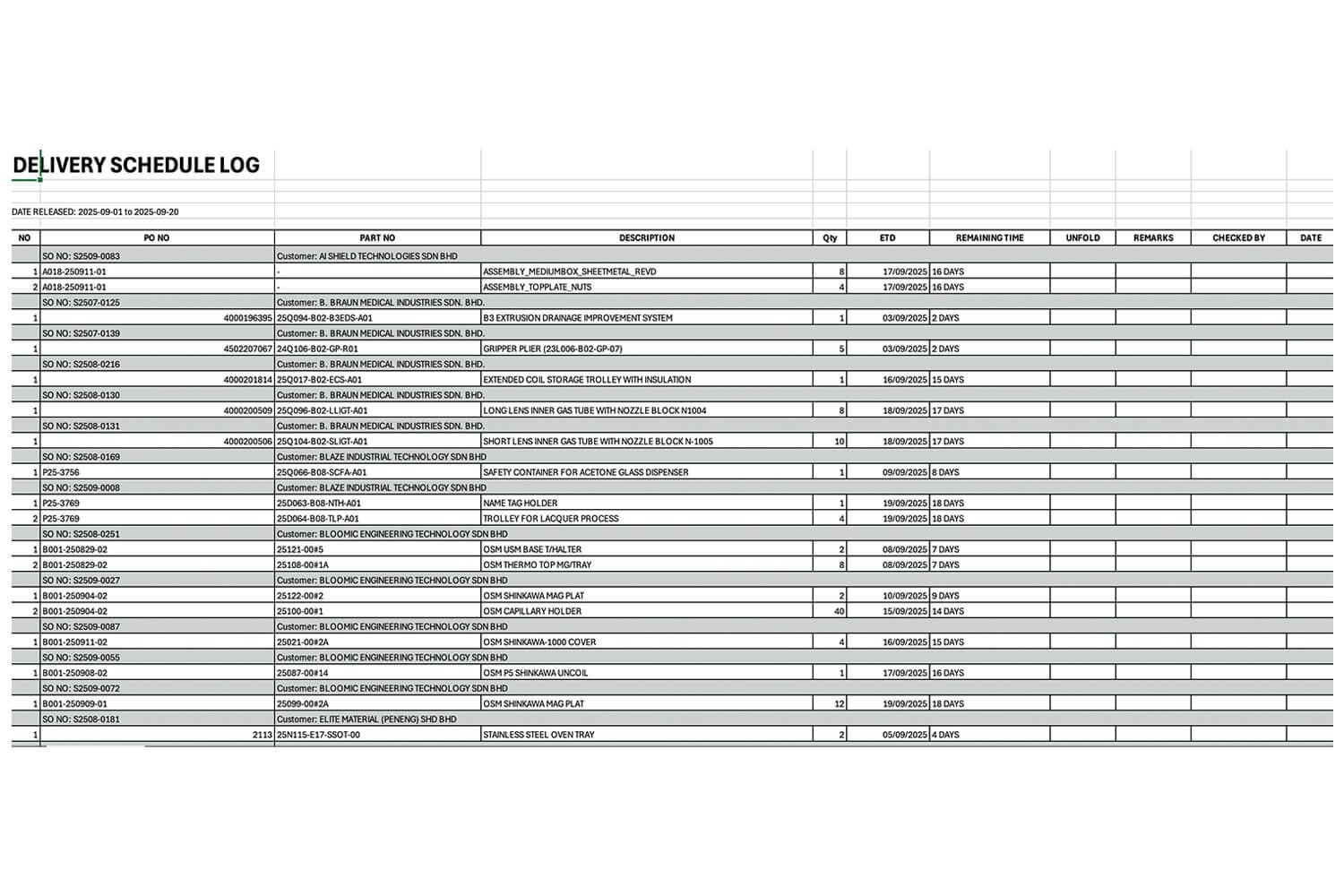

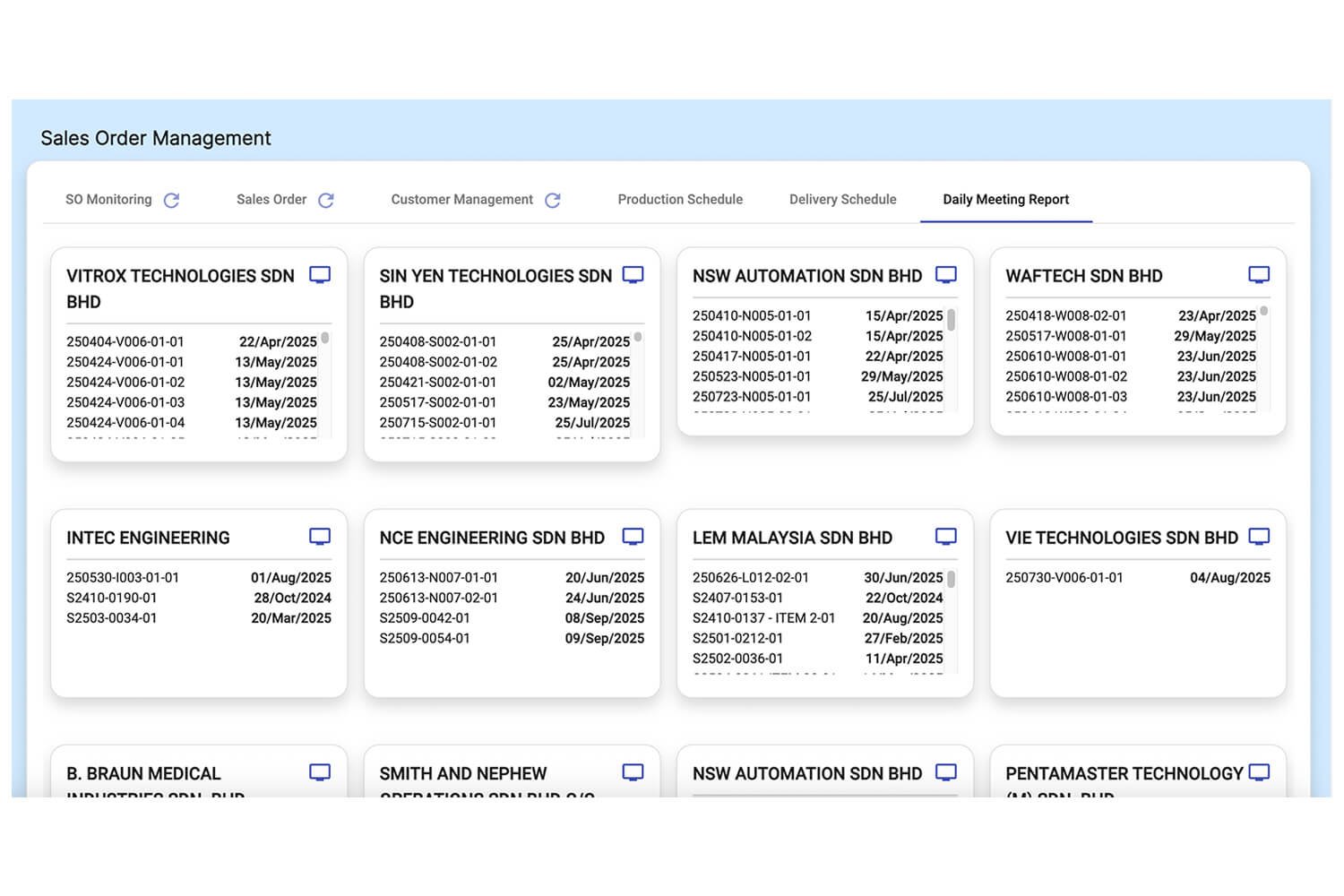

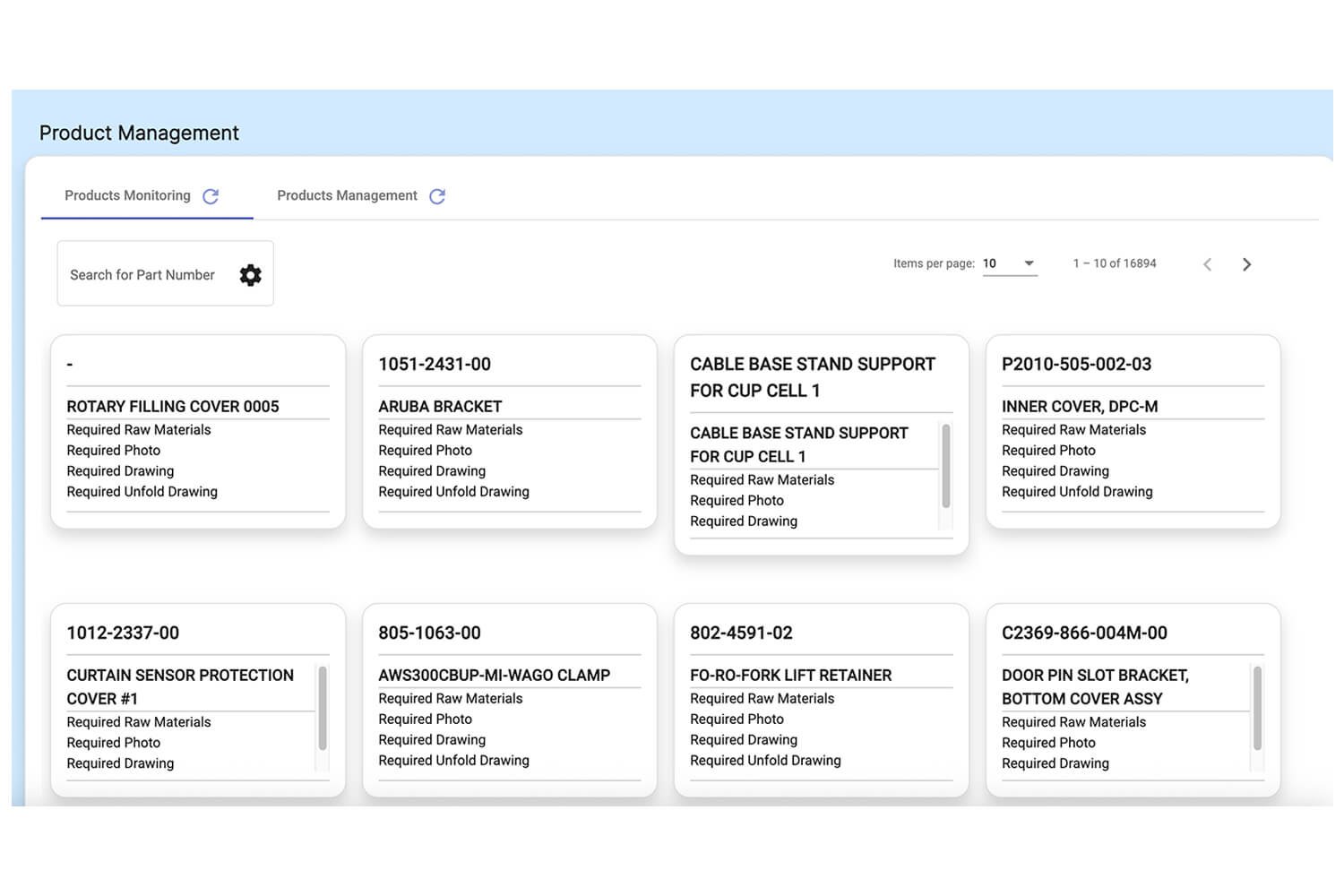

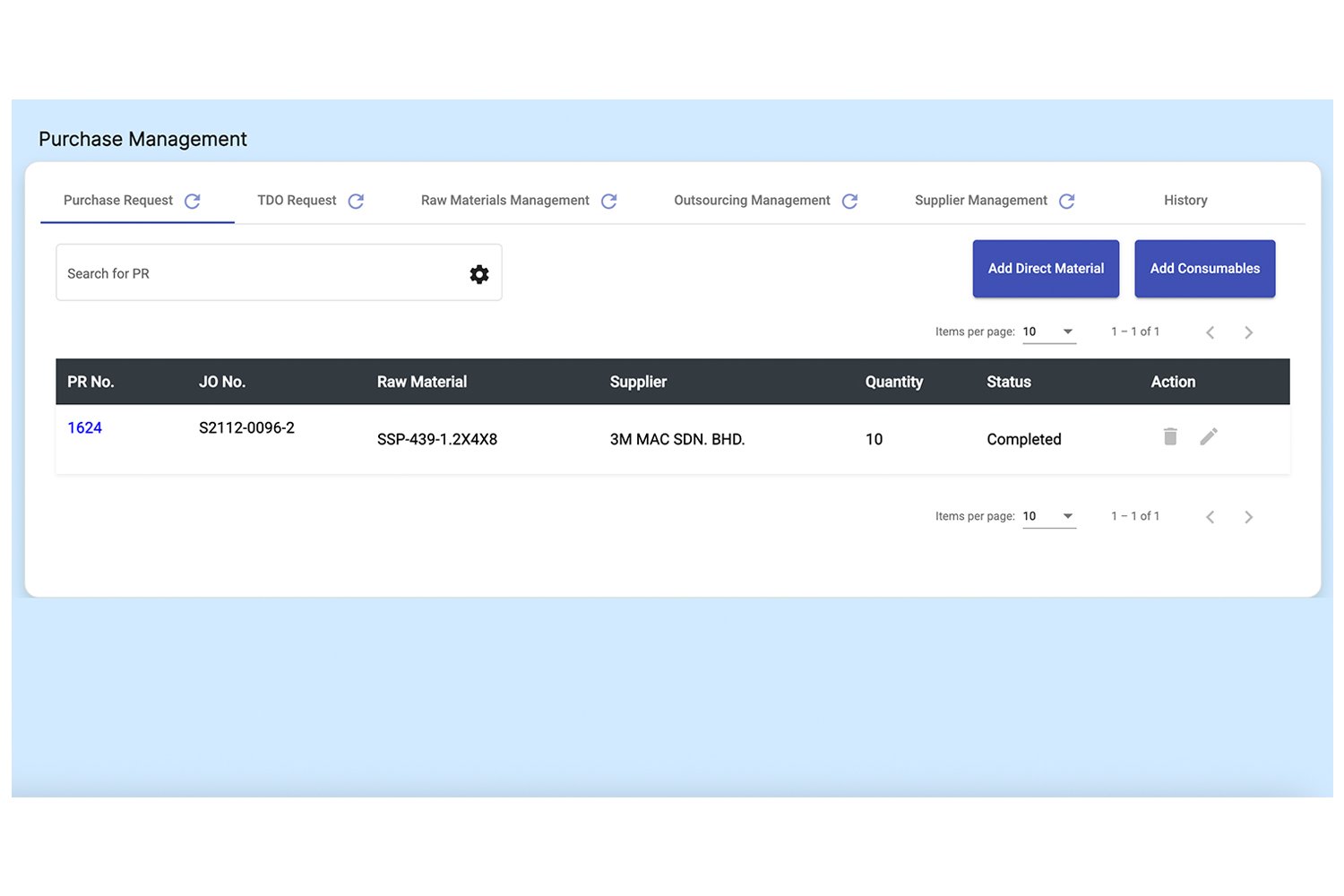

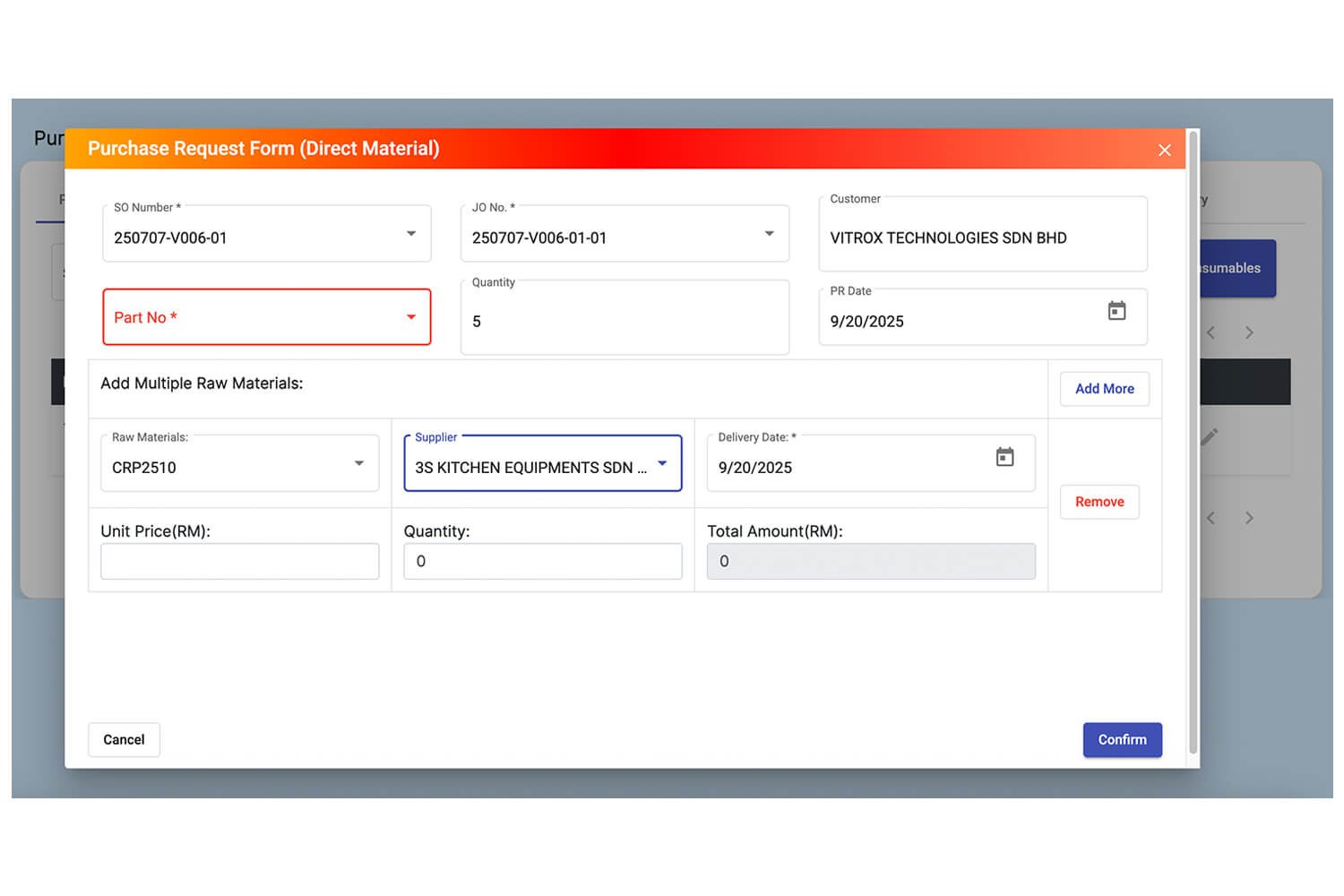

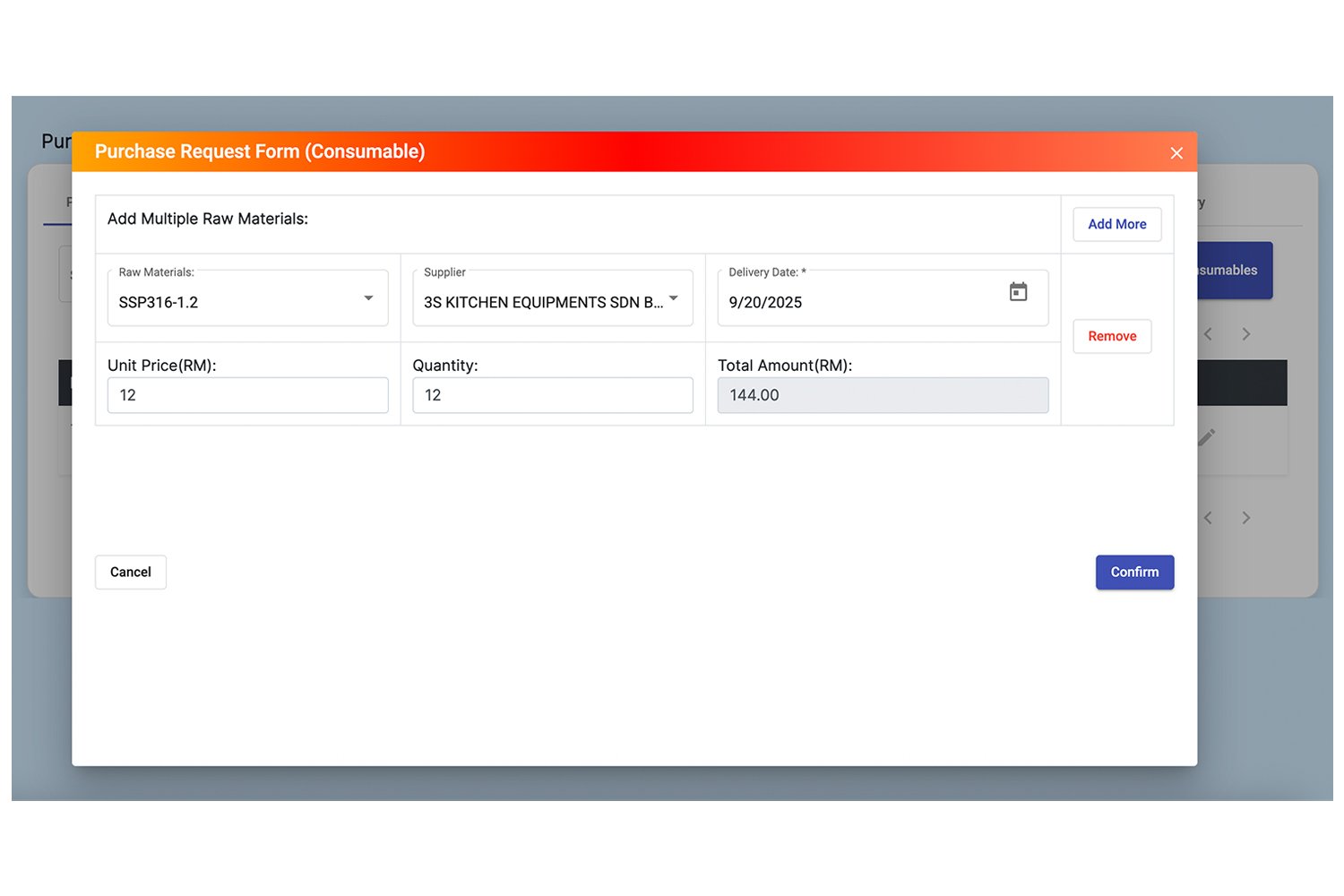

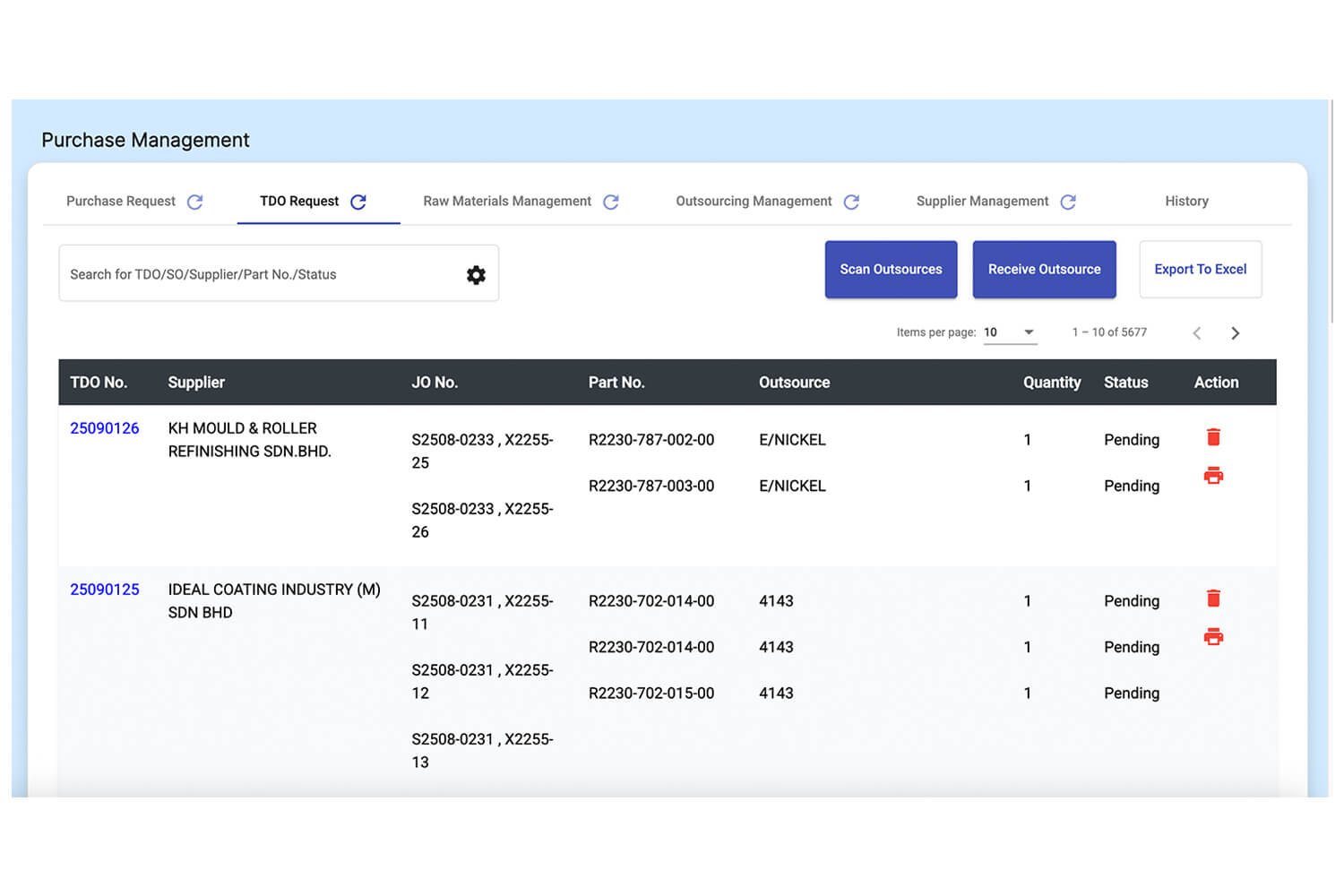

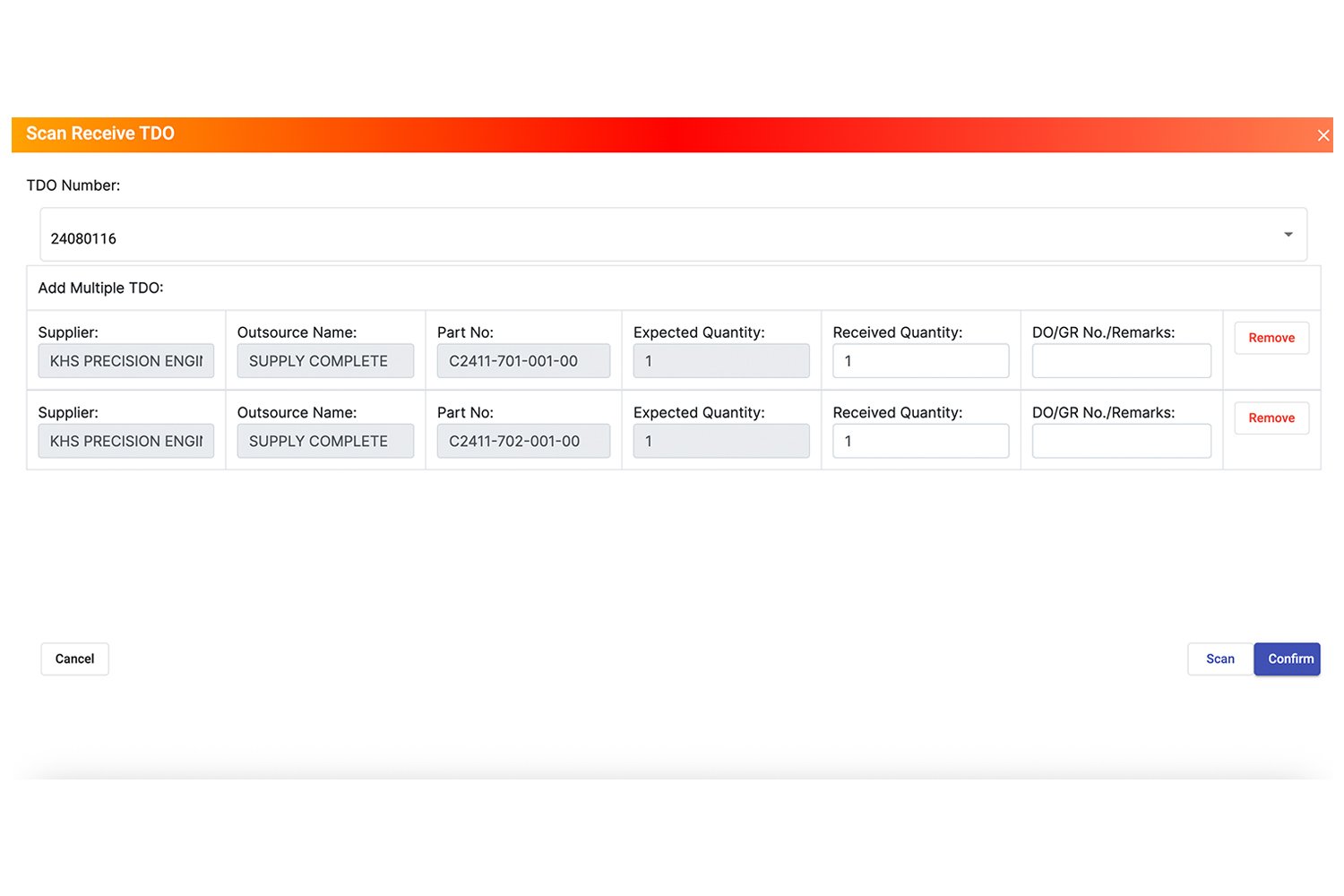

From Raw Materials to Finished Goods

DQ MES provides a comprehensive set of functions to manage the entire production lifecycle. From raw material management and scheduling to quality control and machine integration, every step is designed to boost accuracy and ensure smooth operations.

BENEFIT

Turning Efficiency into Business Growth

By implementing DQ MES, businesses gain complete visibility and control of their manufacturing floor. The system reduces downtime, enhances productivity, and delivers real-time information that helps you stay competitive while achieving consistent operational excellence.

Key Benefits:

PROCESS

From Planning to Continuous Improvement

The DQ MES process transforms traditional production into a smart, data-driven workflow. It starts from planning and material preparation, continues through execution and monitoring, and ends with performance analysis and continuous improvement.

Planning & Scheduling

Material Preparation

Production Execution

Monitoring & Data Collection

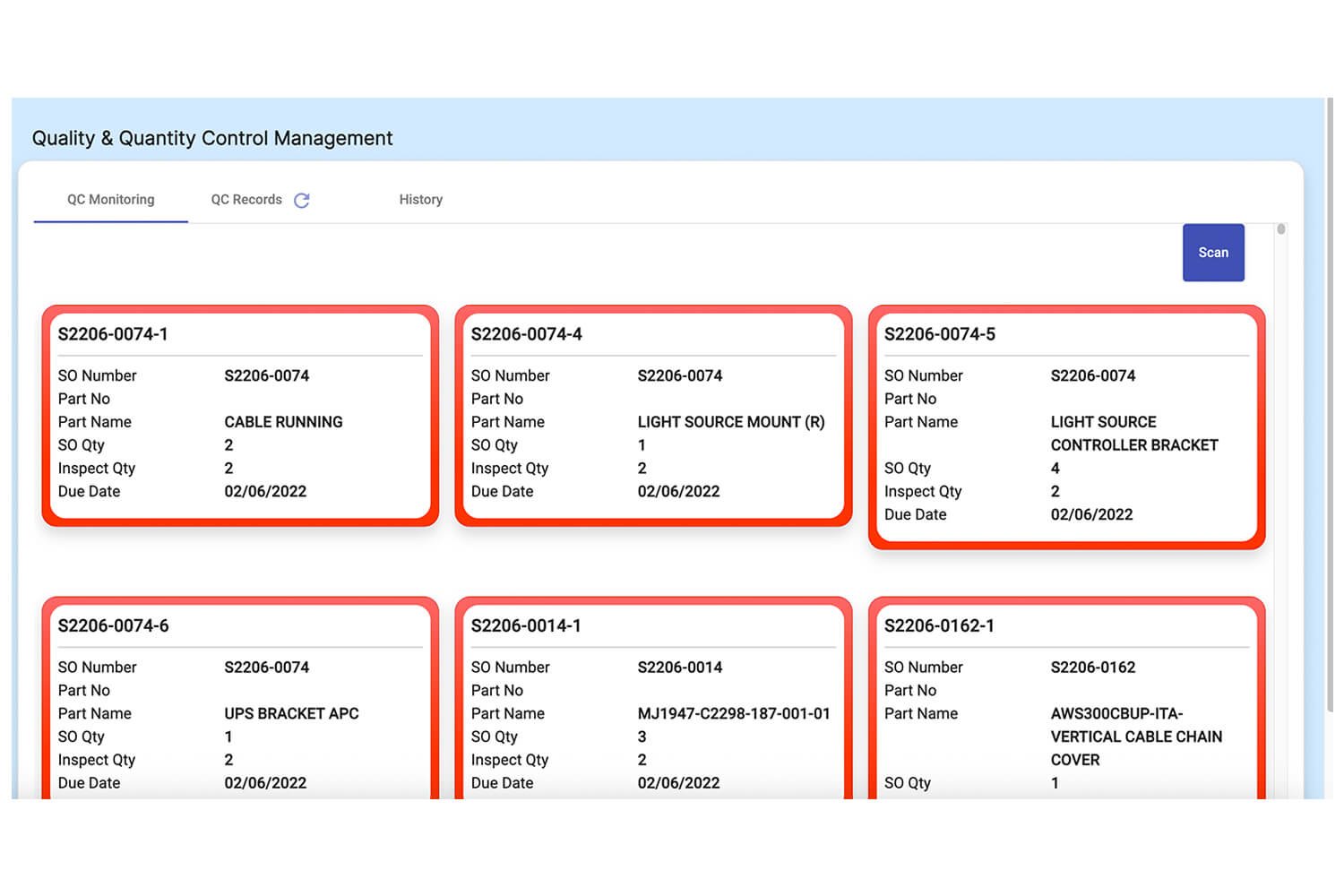

Quality Control

Reporting & Analysis

Continuous Improvement

PORTFOLIO